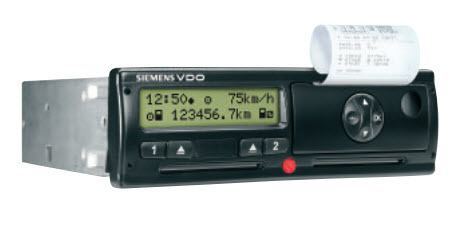

From 15 June 2019, smart tachographs are to be made mandatory for new vehicles. The new Annex 1C compliant tacho aims to reduce administrative processes and digital tachograph tampering.

- You are here:

- Home »

- Archive: December, 2018

Archive Monthly Archives: December 2018

AdBlue checks

AdBlue is a highly purified colorless liquid. It contains demineralized water and urea (32.5%).

AdBlue is used with diesel engines and is also known outside of Europe as DEF, ARLA 32 or AUS 32.

The main active component of AdBlue is ammonia. This is chemically formed by hydrolising automotive urea, which is the main raw material for AdBlue.

Vehicle load security pilot

The Driver and Vehicle Standards Agency (DVSA) has begun a vehicle load security pilot in the north of England. Usually, inspectors only check loads when faced with signs of risk; for example, if curtains are bulging.

Load security issues

Transport authorities' decision to target load security a few years ago has led to more roadside prohibitions.

Kevin Swallow asks if mandatory ADR-style training would solve the issue.

Northumberland-based haulier had its operator's licence curtailed for three months in 2016 for repeated load security issues.

Truck Cab Gym Drives Fitness

An interesting concept to keep drivers fit was introduced into the Stream Space cab of his Mercedes-Benz Actros. Thanks to an initiative by German haulier Spedition Fehrenkotter, driver Heiko Gebhardt has installed a personal fitness studio in the StreamSpace cab of his Mercedes-Benz Actros.